458th Bombardment Group (H)

Consolidated B-24 Liberator

The Consolidated B-24 Liberator was designed by Consolidated Aircraft of San Diego, California. It was known within the company as the Model 32, and a small number of early models were sold under the name LB-30 (LB for Land Bomber). The B-24 was used in World War II by several Allied air forces and navies, and by every branch of the American armed forces during the war, attaining a distinguished war record with its operations in the Western European, Pacific, Mediterranean, and China-Burma-India Theaters.

Often compared with the better-known Boeing B-17 Flying Fortress, the B-24 was a more modern design with a higher top speed, greater range, and a heavier bomb load; it was also more difficult to fly, with heavy control forces and poor formation-flying characteristics. Popular opinion among aircrews and general staffs tended to favor the B-17’s rugged qualities above all other considerations in the European Theater. The placement of the B-24’s fuel tanks throughout the upper fuselage and its lightweight construction, designed to increase range and optimize assembly line production, made the aircraft vulnerable to battle damage. The B-24 was notorious among American aircrews for its tendency to catch fire. Its high fuselage-mounted “Davis wing” also meant it was dangerous to ditch or belly land, since the fuselage tended to break apart. Nevertheless, the B-24 provided excellent service in a variety of roles thanks to its large payload and long range and was the only bomber to operationally deploy the United States’ first forerunner to precision-guided munitions during the war, the 1,000 lb. AZON guided bomb.

XB-24 in flight

The Liberator was conceived in January 1939, when General “Hap” Arnold invited Consolidated to come up with a design superior to Boeing’s Flying Fortress. The company’s preliminary data was impressive enough to warrant a contract for a prototype, and the design team under Isaac Laddon went to work in earnest. Their first consideration was range, and they selected the wing design by David Davis for its great efficiency; the wings were shoulder mounted, allowing a capacious fuselage and a twin rudder and fin assembly was chosen. The aircraft had a tricycle undercarriage and the bomb bay was divided into front and rear compartments, with unique roller-type doors which retracted up the sides from the central keel beam.

In the first Liberator, Consolidated Model 32, there was provision for a few hand-held .30-caliber machine guns, and the gleaming prototype, dubbed XB-24 by the Air Corps, flew for the first time on December 29, 1939. By then the Air Corps had already placed an order for seven YB-24s, and thirty-six B-24As for evaluation. The French and British ordered 284 aircraft between them.

Weighing 41,000 pounds gross, the XB-24 was powered by four 1200 horsepower Pratt & Whitney Twin Wasps. The wingspan was 110 feet, and the bomber was 63 feet long. The test flights of the lumbering aircraft were successful, although the maximum speed was slightly less than that of the current model of the Flying Fortress. The range requirements were more than met. During 1940 the YB-24 was delivered, the only difference between it and the XB-24 being the addition of rudder de-icing boots on the tail and wings, increased gross weight, and airscrew spinners which were later discarded.

The fall of France led to their order being transferred to the British, and the first production Liberators were six LB-30As [left], paid for in cash by England. They were built to British specifications and were used on the Return Ferry Service between Canada and Scotland. The next twenty aircraft, also for England, were known as Liberator Is, and were the first to see operational service. Bristling with aerials and a gun pack containing four 20-mm cannon, they quickly proved themselves in the desperate campaign against the German U-Boats.

The Army Air Forces received their first B-24A in June 1941, one of the nine built. These aircraft went to Ferrying Command, operating between Canada and England. One of the B-24As pioneered the South Atlantic ferry route and in September two of the Liberators flew the Harriman mission to Moscow, and yet another B-24A was the first aircraft over the Greenland ice cap. Two had been detailed to fly reconnaissance over Japanese positions in the Marshall and Carolina Islands, but only one had reached Hawaii by 7 December 1941, and it was destroyed in a hangar at Hickham Field.

The next model was the Liberator II, unique to the Royal Air Force and with an extended nose adding three feet to the aircraft’s length. Four gun Boulton-Paul .303 turrets were fitted in the mid-upper position and in the tail. The first of the Liberator IIs crashed on 2 June 1941, killing Consolidated test pilot William Wheatley, but other Liberator IIs went on to do magnificent work, equipping two squadrons of Bomber Command and three of Coastal Command. Unarmed Liberator IIs flew with the Return Ferry Service, British Overseas Airways, Qantas and Southern Cross Airways, and one was Winston Churchill’s personal transport, the “Commando”.

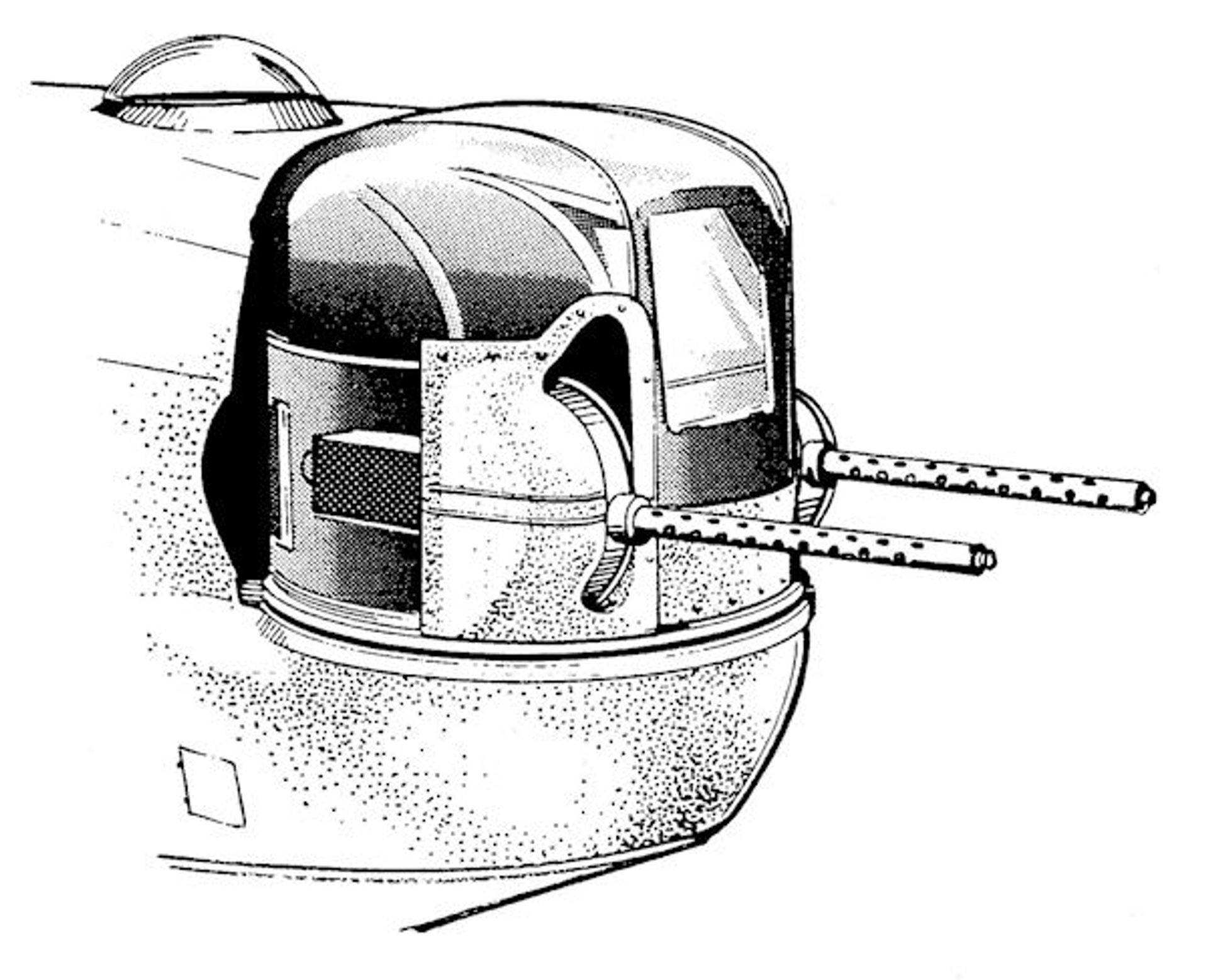

After Pearl Harbor the United States took over fifty-one undelivered Liberator IIs; called LB-30s by the air force, three of these Liberators attacked Kendari on Celebes on 16 January 1942, the first time American-manned Liberators took part in a bombing attack. Others went to Alaska, Hawaii and Panama, while some were used for training and as transports.The XB-24B was a reworking of the XB-24, with self-sealing tanks, armor and turbo superchargers which resulted in a top speed of 310 miles per hour. This led to nine B-24Cs, which carried a Martin upper turret and Consolidated tail turret, each with two of the .50-caliber machine guns which were quickly replacing the lighter .30 as hard lessons were learned in combat.

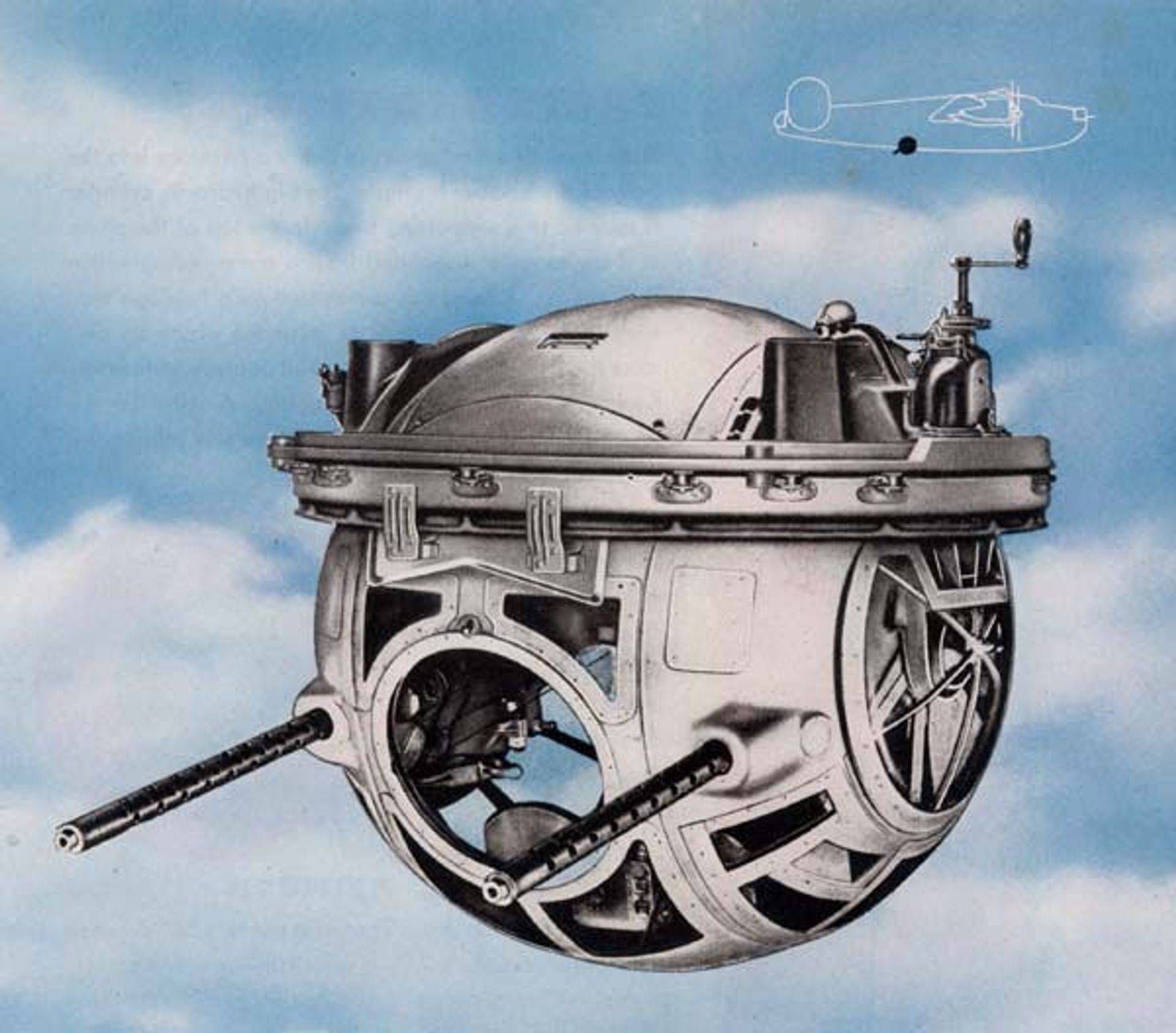

The following model of the Liberator was the B-24D [right], and production went into high gear. Consolidated built 2,415 B-24Ds at their San Diego plant 303 at Fort Worth, and Douglas built ten at Tulsa in Oklahoma. Early B-24Ds had a hand-held nose gun, a Bendix lower turret and four other guns, but later aircraft were equipped with a single ventral gun which fired through the camera hatch, and still later two more nose guns were added, plus waist guns, meaning that the Liberator carried ten defensive guns in all. The bomb load was increased to 12,800 pounds, and maximum gross weight climbed to 71,200 pounds. The hand-held tunnel gun was eventually replaced by the Sperry ball turret.

The first American B-24D unit in combat was the Halpro force – twenty-three Liberators under the command of Colonel Harry Halverson. They were in the Middle East by the middle of 1942, and attacked the Ploesti oilfields, harassed Axis shipping, and helped fill the breach during the crucial phases of the campaign against Rommel. The 98th Bomb Group joined the Ninth Air Force and went into combat on 1 August 1942, B-24Ds went to war with the Eighth Air Force’s 93rd Bomb Group on 9 October 1942, and in the Southwest Pacific the 90th Bomb Group took over the heavy bomber role in Kenney’s Fifth Air Force in November 1942.

By the end of the war Liberators would fly with every American air force, and those of several other countries.The British called their B-24Ds Liberator IIIs when equipped to their specifications, or Liberator IIIAs with American equipment on aircraft supplied under Lend-Lease, and most went to Coastal Command. The U.S. Navy received B-24Ds as YB4Y-1s and these aircraft went to both the Pacific and European Theaters. The first C-87 Liberator Expresses were B-24Ds converted as transports on the production line, and in all 280 C-87s and six C-87As were built, all at Fort Worth. Another B-24D was modified as the XB-41, with fourteen machine guns and provision for 11,000 rounds of ammunition; this was to be a “bomber escort” but was never tested operationally.

The B-24E differed little from its predecessor, and one was modified in late 1943 as the XC-109, a fuel tanker with nose and bomb bay fuel tanks. Combat in Europe and the Pacific had revealed that the B-24D was vulnerable to head-on attack, and various solutions were tried. Twin nose guns, lashed together, were used in Europe, but they were difficult to use, although some crews maintain it was a better arrangement than the later nose turret, as far as overall performance of the aircraft was concerned. The 90th Bomb Group in the Southwest Pacific pioneered the installation of a consolidated tail turret in the Liberator’s nose, and similarly successful work was carried out at the Hawaiian Air Depot. Later Navy B-24Ds were equipped with the distinctive Erco turret, which extended the nose about three feet. Some B-24Ds were fitted with twin waist guns, the most successful experiment being in the 44th Group, where Lieutenant Bill Strong and his crew designed a special mounting for use in their plane, “Baldy and His Brood“.

Ford Motor Company began their Liberator production with 480 B-24Es, built at the huge Willow Run plant in Michigan, and another 311 B-24Es were built by Douglas and Consolidated at Fort Worth. The sole XB-24F was a modification of the B-24D, with a thermal de-icing system.There were 430 B-24Gs, all built in Dallas by the fourth producer of the Liberator, North American Aviation. These aircraft were not all the same – the first twenty-five were without the electrically powered Emerson nose turret (below), and although later aircraft were equivalent to the B-24H, they were not re-designated.

The first Liberator to be fitted with a nose turret on the production line was the B-24H, and Consolidated built 738 at Fort Worth, with Emerson electric turrets. Another 1,780 were built at Willow Run, and 582 at Tulsa, Ford and Douglas using the Motor Products hydraulic turret.

The most prolific model of the Liberator was the B-24J, built at all five factories and differing little in essentials from the B-24H. Around 1,200 went to the Royal Air Force, others became F-7As and F-7Bs, equipped with six aerial cameras, and more went to the Navy, where they were still called PB4Y-1s, carrying the Erco nose turret. Ford built 1,587 B-24Js, North American 536, Douglas 205, Consolidated Fort Worth 1,558 and San Diego 2,792. There were 6,678 B-24Js in all.

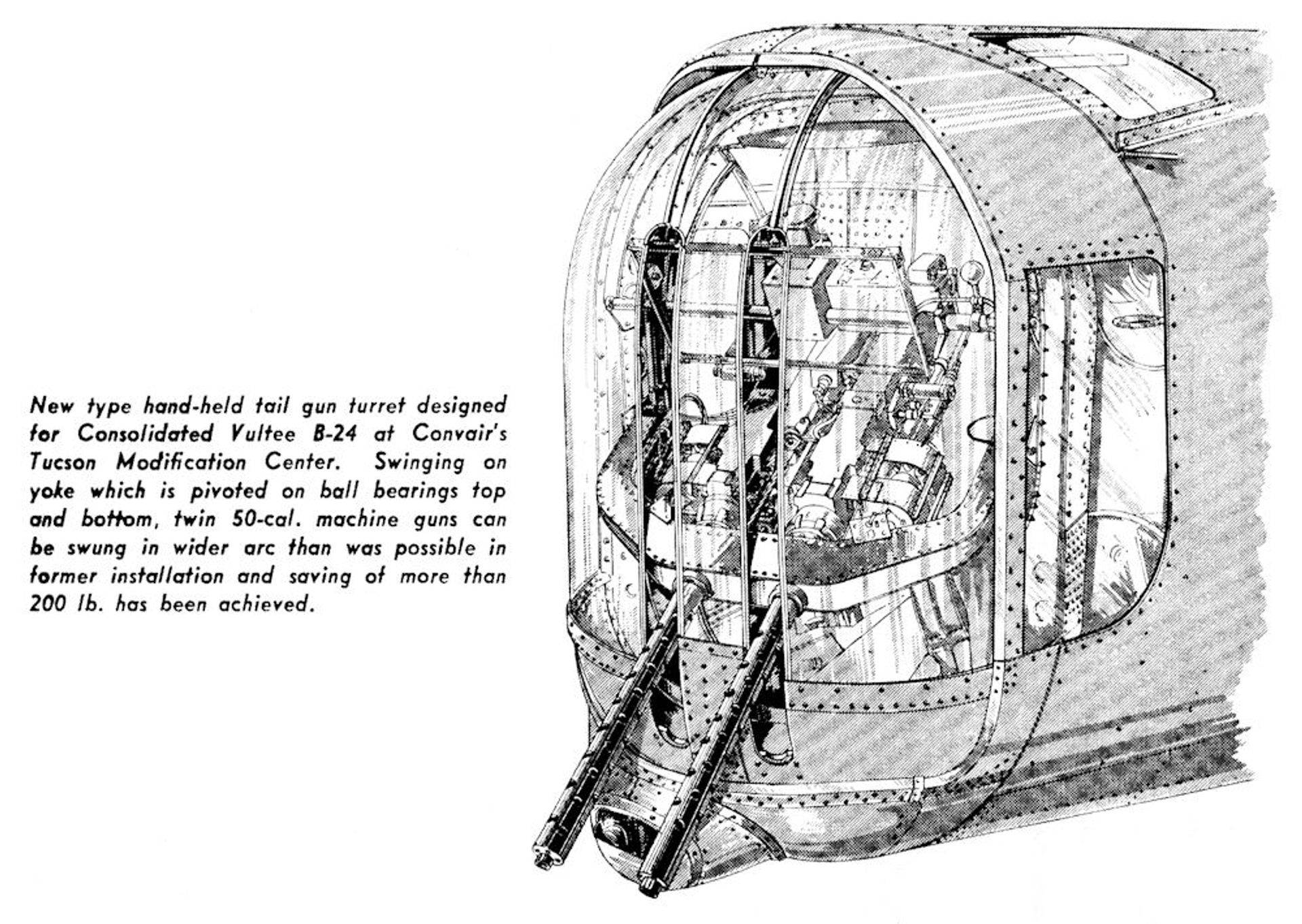

Similar to the B-24J, the B-24L was fitted with a lighter tail turret designed by Consolidated’s Tucson modification center. This gave a greater field of fire, was easier to manipulate and saved some two hundred pounds in weight. Ford produced 1,250 aircraft at Willow Run, and the other 417 were built by Consolidated at San Diego.

The last model of the Liberator to see quantity production was the B-24M, which was fitted with a light power tail turret, and 2,593 aircraft were built at San Diego and Willow Run. The XB-24P was a modified B-24D which was used for fire control research, and the XB-24Q was a B-24L with an experimental radar-controlled tail installation.

Back in 1942 it had been reasoned that the B-24 would have greater stability with a single fin, and a B-24D was modified and designated XB-24K in 1943. The high tail test aircraft proved the theory regarding stability and control and in April 1944 the decision was made that the twin tail assembly would no longer be used. However, only the XB-24N and seven YB-24Ns were built before 31 May 1945, when Liberator production was ended, and other orders for the single-tailed B-24N were cancelled. The Navy received 739 single-tailed Liberators which they had contracted for – these were heavily modified and known as PB4Y-2 Privateers.

(Courtesy: 461st Bombardment Group)

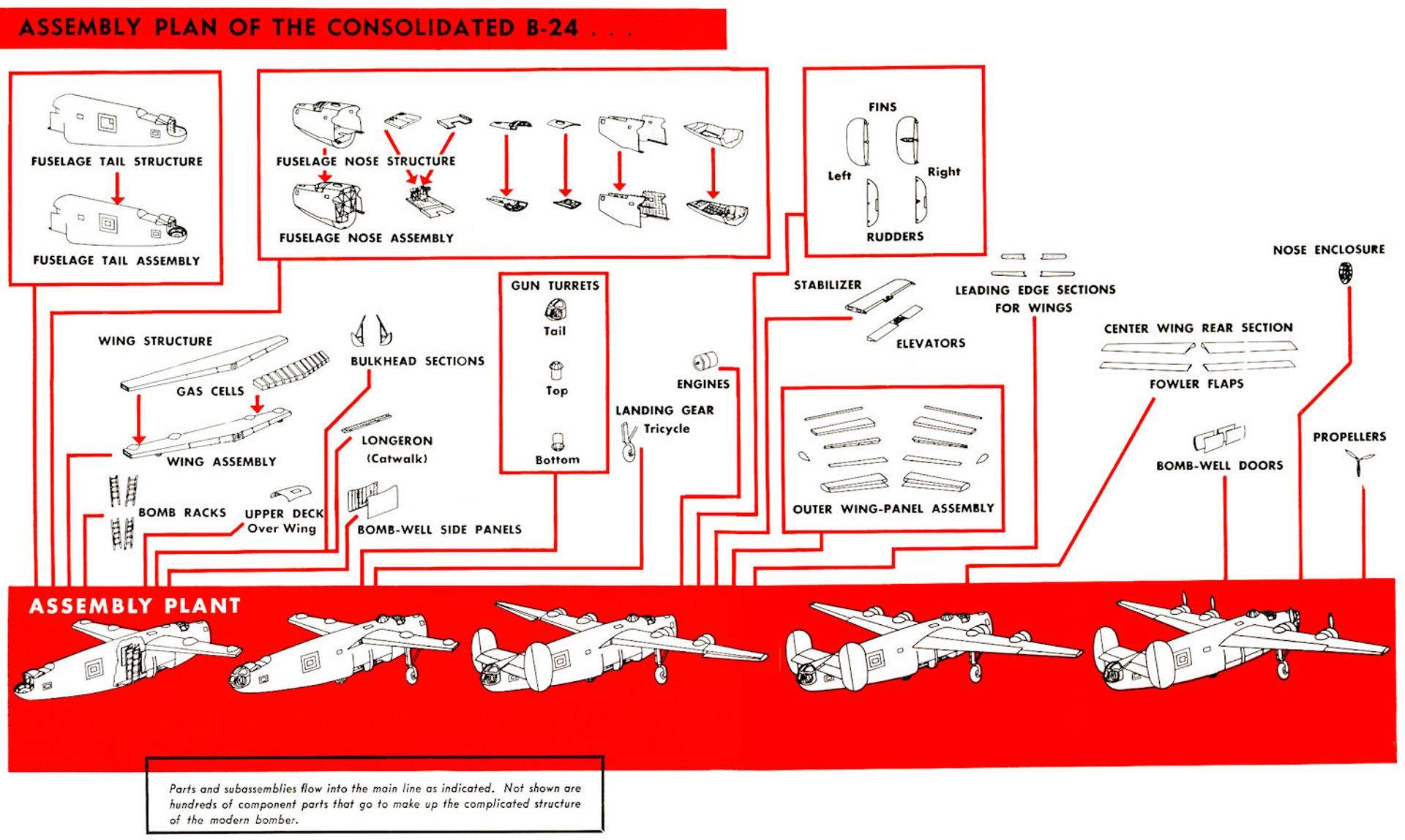

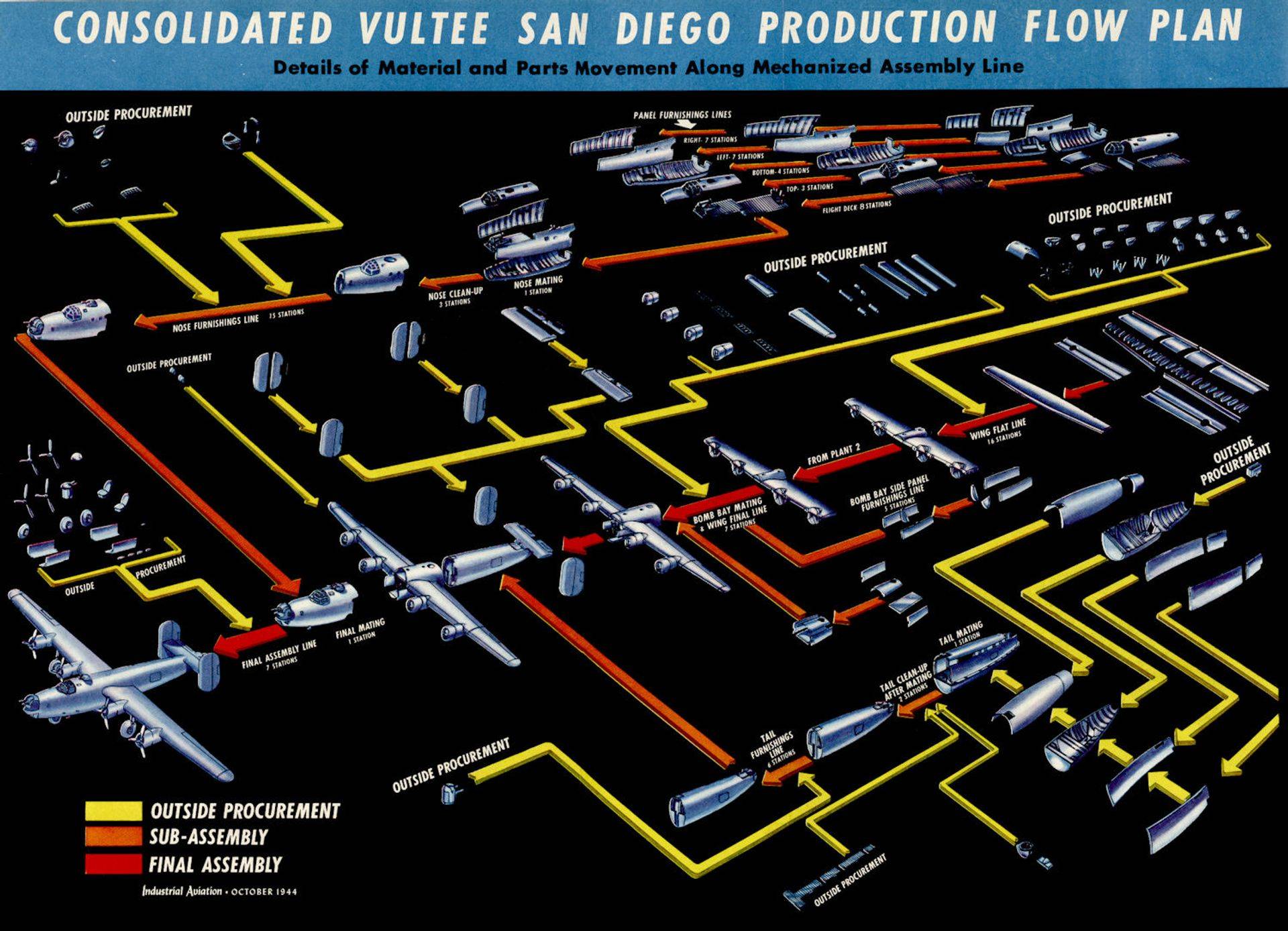

Production

The first mass-produced model was the B-24D (Liberator III in British service), entering service in early 1943. It had turbocharged engines and increased fuel capacity. Three more 0.50 caliber (12.7 mm) machine guns brought the defensive armament up to 10 machine guns. At 59,524 lb (27,000 kg) maximum takeoff weight, it was one of the heaviest aircraft in the world; comparable with the British “heavies” the Stirling, Lancaster and Halifax.

Production of B-24s increased at an astonishing rate throughout 1942 and 1943. Consolidated Aircraft tripled the size of its plant in San Diego and built a large new plant outside Fort Worth, Texas. More B-24s were built by Douglas Aircraft in Tulsa, Oklahoma. The North American plant B in the city of Grand Prairie, Texas started production of B-24Gs and B-24J in 1942.[citation needed] None of these were minor operations, but they were dwarfed by the vast new purpose-built factory constructed by the Ford Motor Company at Willow Run near Detroit, Michigan. Ford broke ground on Willow Run in the spring of 1941, with the first plane coming off the line in October 1942. It had the largest assembly line in the world (3,500,000 ft). At its peak, the Willow Run plant produced 650 B-24s per month in 1944. By 1945, Ford made 70% of all B-24s in two nine-hour shifts. Pilots and crews slept on 1,300 cots at Willow Run waiting for their B-24s to roll off the assembly line. At Willow Run, Ford produced half of 18,000 total B-24s.

Each of the B-24 factories was identified with a production code: Consolidated/San Diego, CO; Consolidated/Fort Worth, CF; Ford/Willow Run, FO; North American/Dallas, NT; and Douglas/Tulsa, DT.

In 1943, the model of Liberator considered by many the “definitive” version was introduced. The B-24H was 10 inches longer, had a powered gun turret in the upper nose to reduce vulnerability to head-on attack, and was fitted with an improved bomb sight, autopilot, and fuel transfer system. Consolidated, Douglas and Ford all manufactured the B-24H, while North American made the slightly different B-24G. All five plants switched over to the almost identical B-24J in August 1943. The later B-24L and B-24M were lighter-weight versions and differed mainly in defensive armament.

As the war progressed, the complexity of servicing the Liberator continued to increase. The B-24 variants made by each company differed slightly, so repair depots had to stock many different parts to support various models. Fortunately, this problem was eased in the summer of 1944, when North American, Douglas, and Consolidated Aircraft at Fort Worth stopped making B-24s, leaving only the Consolidated plant in San Diego and the Ford plant in Willow Run.

In all, 18,482 B-24s were built by September 1945. Twelve thousand saw service with the USAAF, with a peak inventory in September 1944 of 6,043. The U.S. Navy received 977 PB4Y-1s (Liberators originally ordered by the USAAF) and 739 PB4Y-2 Privateers, derived from the B-24. The Royal Air Force received about 2,100 B-24s equipping 46 bomber groups and 41 squadrons; the Royal Canadian Air Force (RCAF) 1,200 B-24Js; and the Royal Australian Air Force (RAAF) 287 B-24Js, B-24Ls, and B-24Ms. Liberators were the only heavy bomber flown by the RAAF in the Pacific.

(Courtesy: Wikipedia)

Collings Foundation Liberator

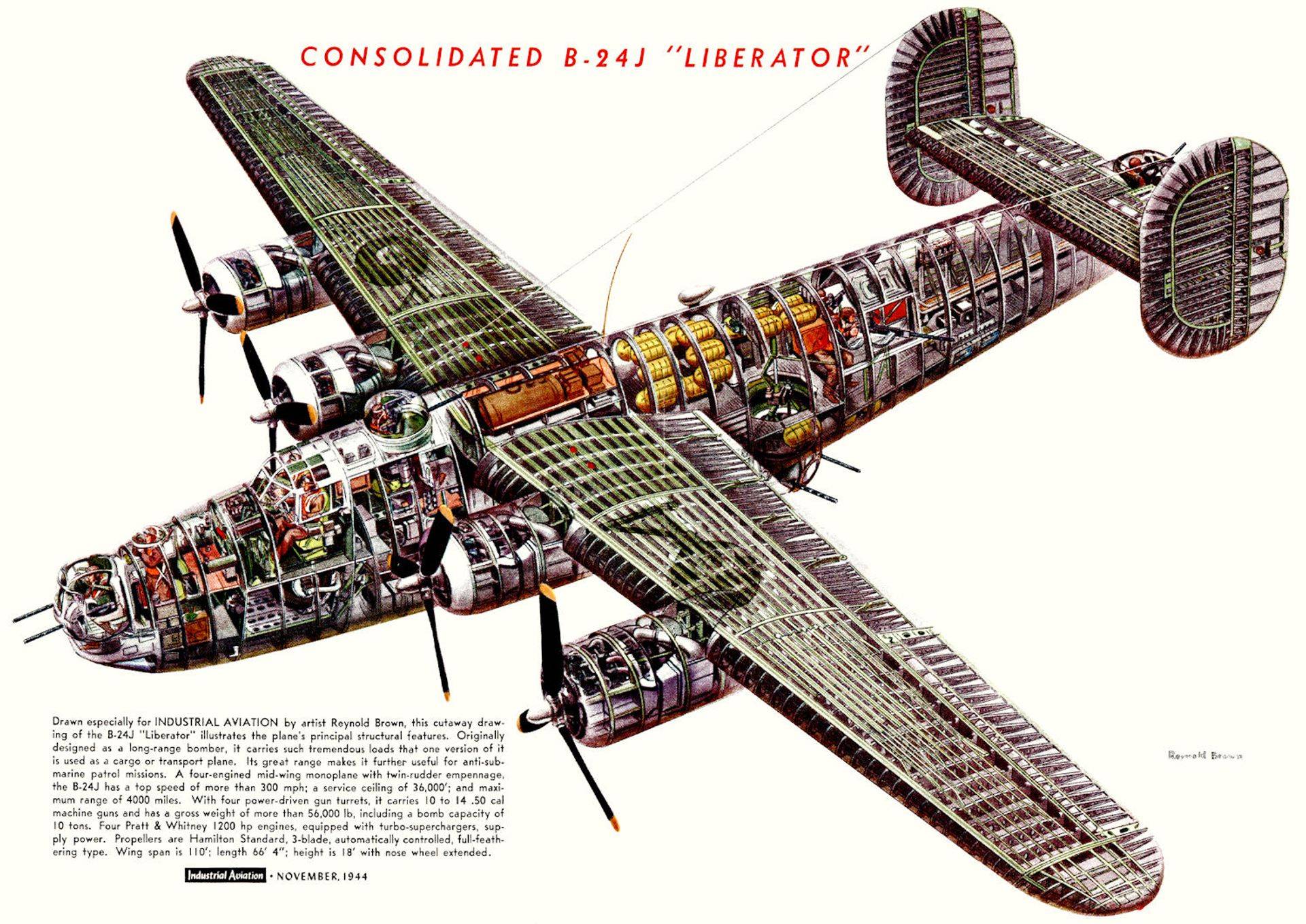

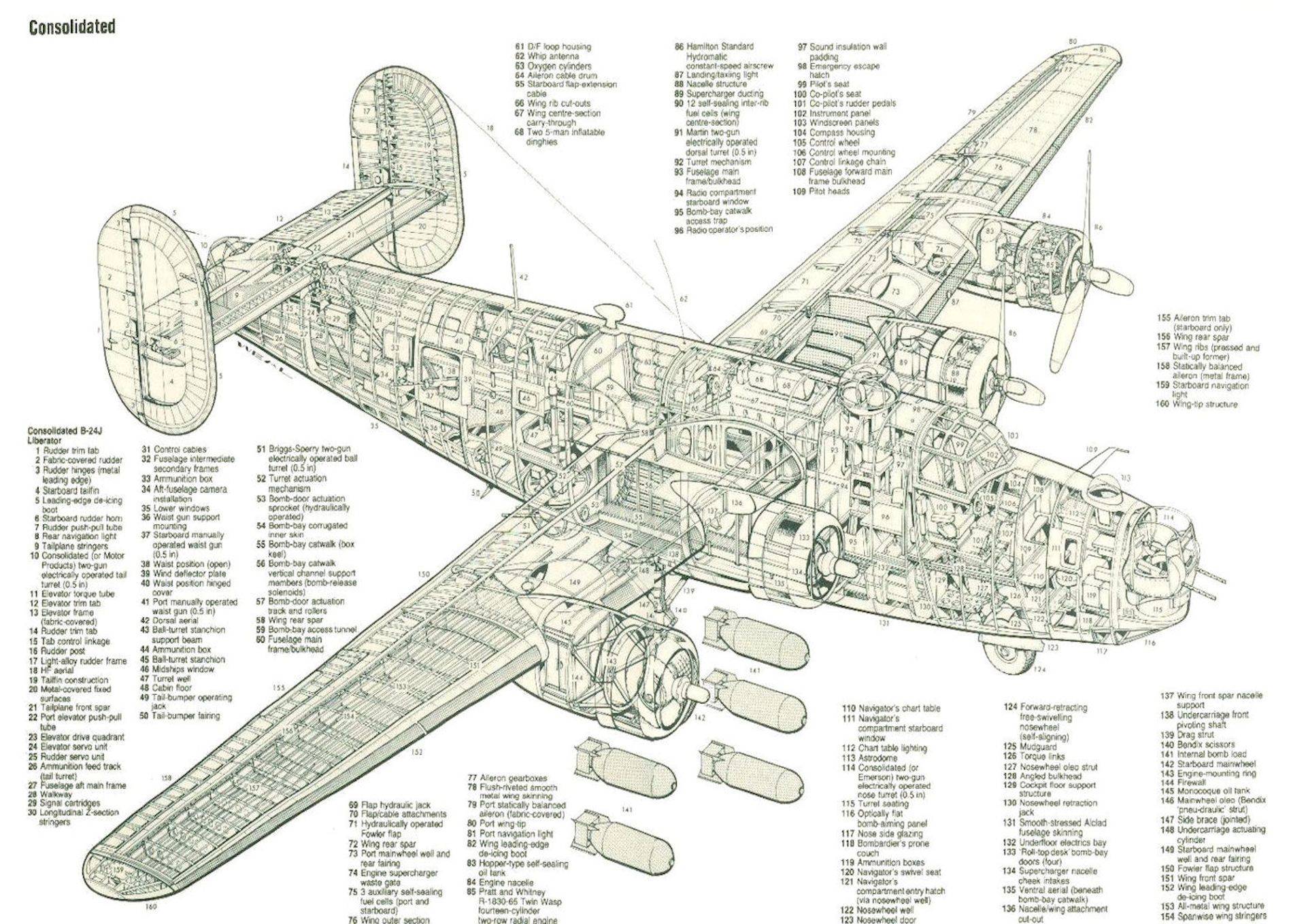

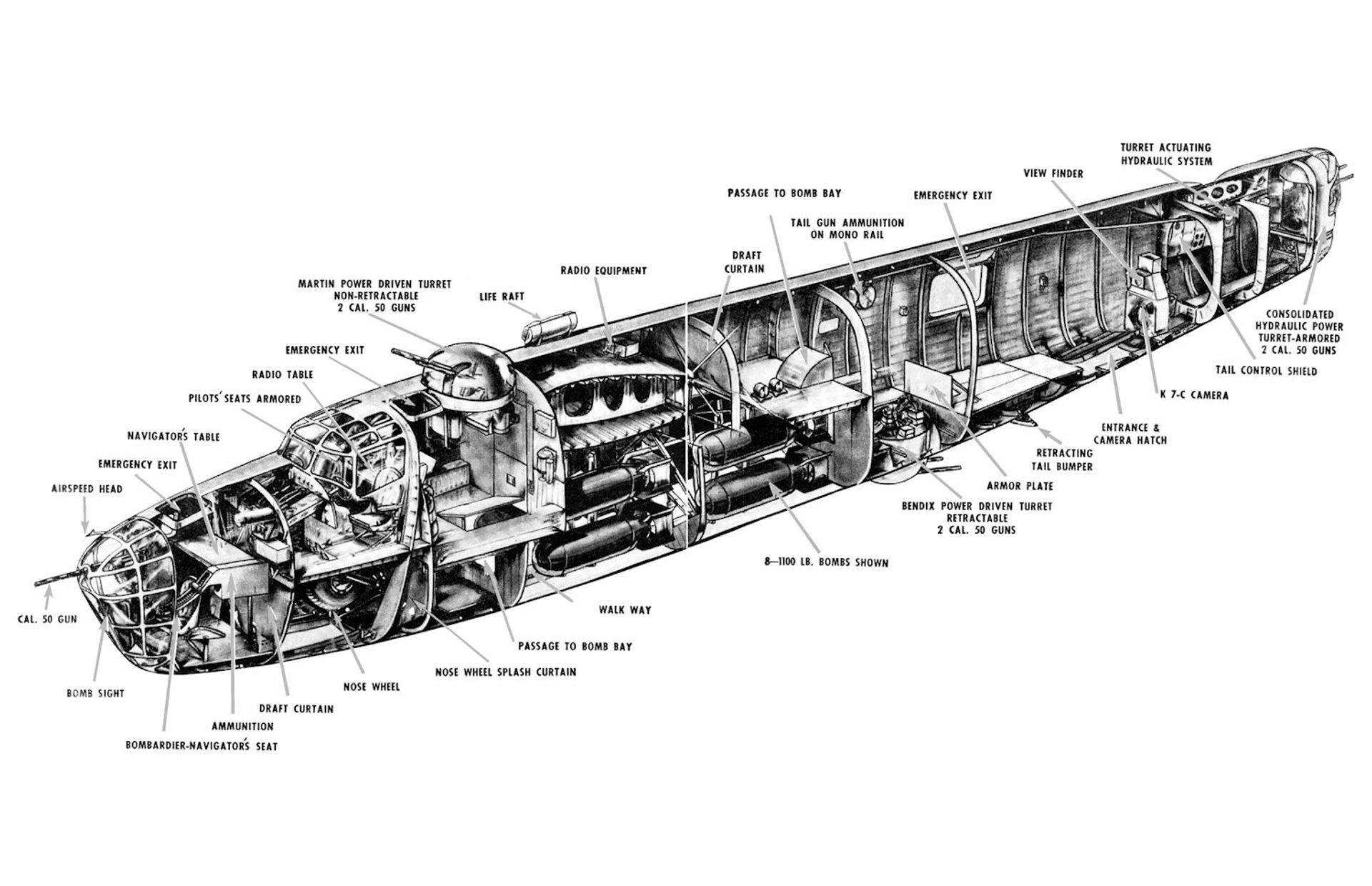

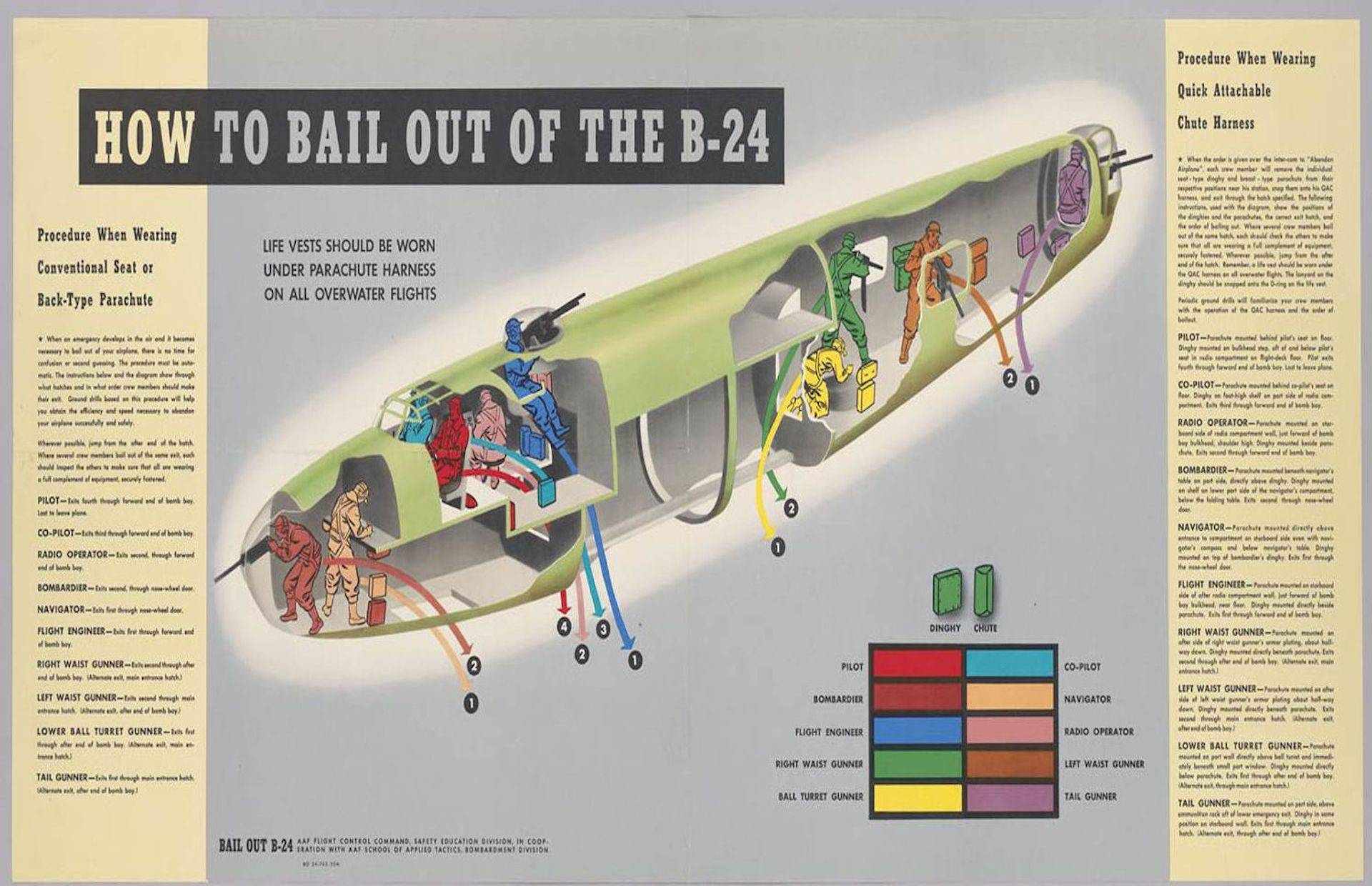

Cutaway images

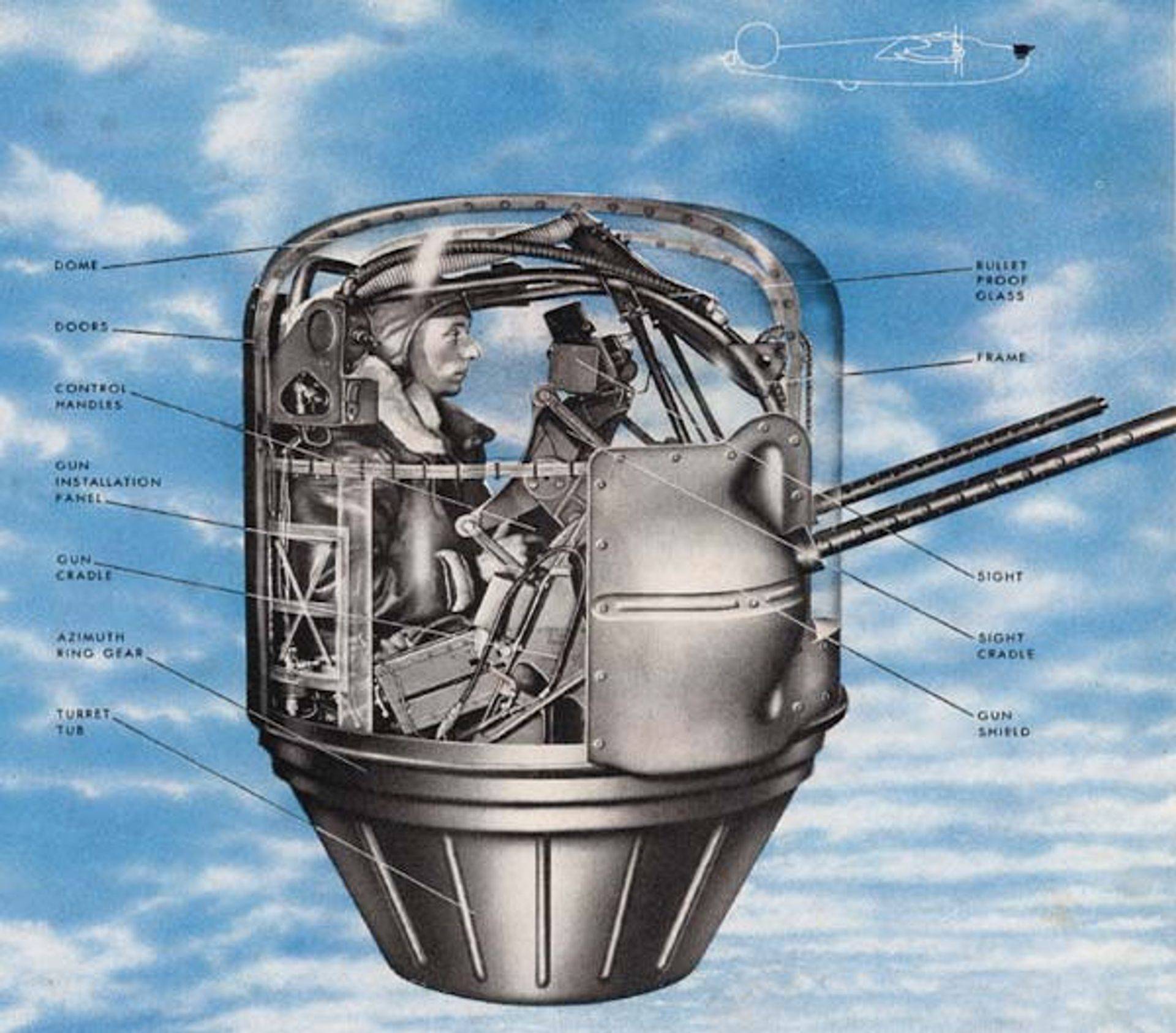

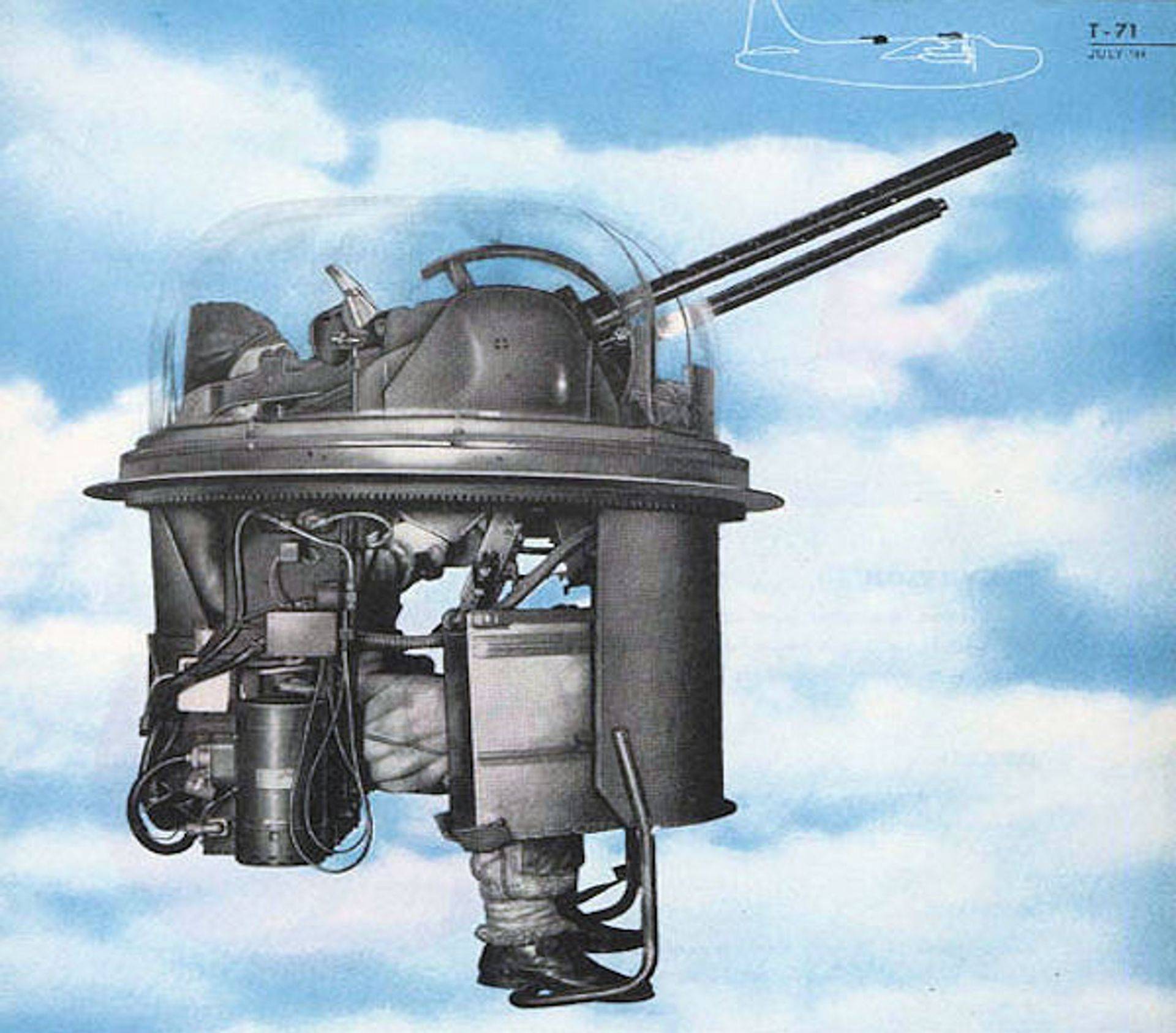

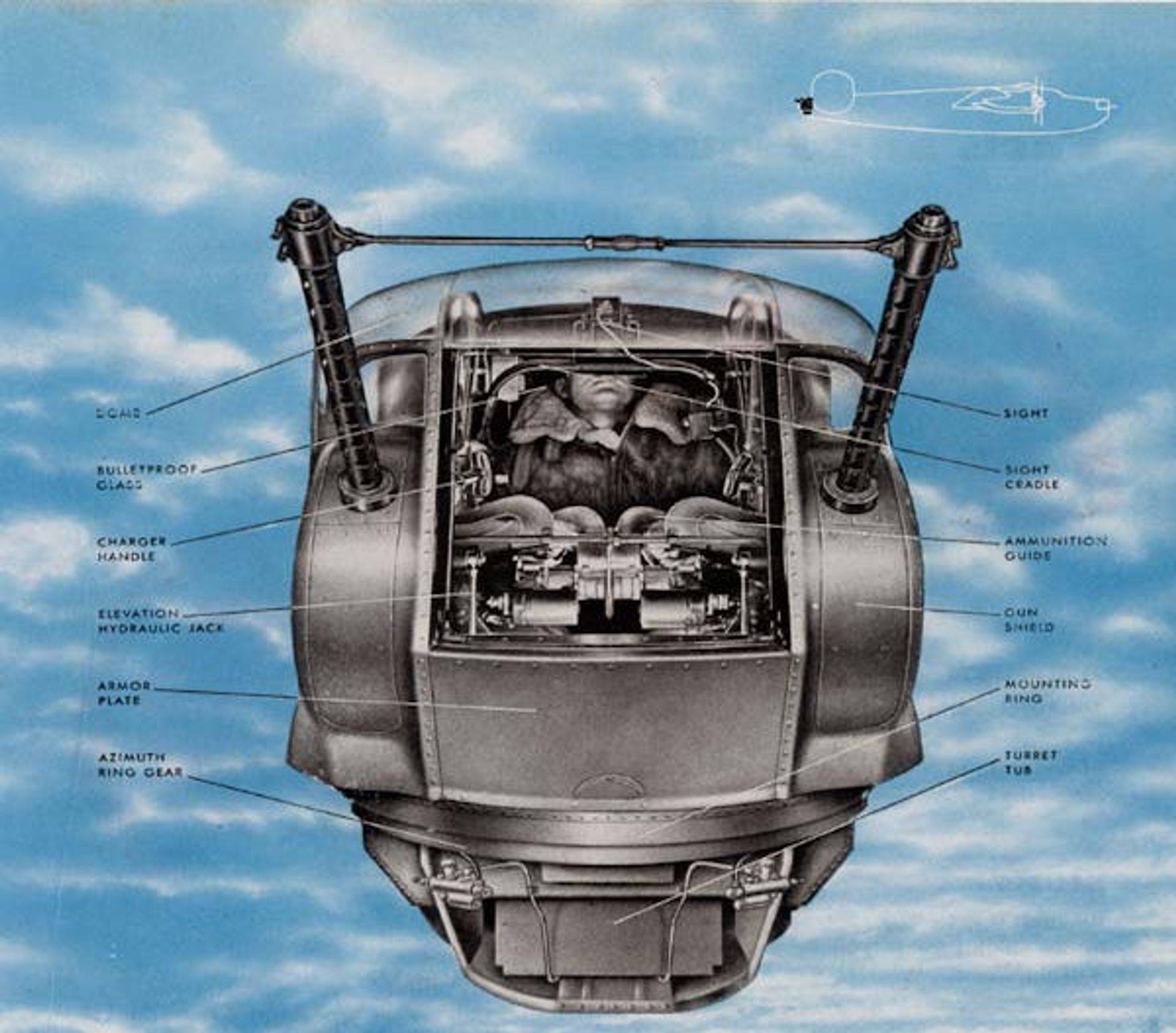

Gun Positions

Above images from HyperWar.com Aircrewman’s Gunnery Manual

Click each image for more info

Waist Gun Position – Sgt DeSales Glover of Crew 33

Specification of B-24J Liberator

Four Pratt & Whitney R-1830-65 Twin Wasp fourteen-cylinder air-cooled radial engines with General Electric B-22 turbo superchargers rated at 1200 hp at 2700 rpm for takeoff and maintaining this power as a military rating up to 31,800 feet.

Performance

Maximum speed 300 mph at 30,000 feet, 277 mph at 20,000 feet. Maximum continuous speed 278 mph at 25,000 feet. Usual combat operating speed was 180-215 mph at between 10,000 and 25,000 feet. Initial climb rate 1025 feet per minute. At a takeoff weight of 56,000 pounds, an altitude of 20,000 feet could be reached in 25 minutes. Service ceiling 28,000 feet at 56,000 pound takeoff weight. Range and endurance with a 5000-pound bomb load was 1700 miles in 7.3 hours at 25,000 feet (all-up weight of 61,500 pounds) with 2364 US gallons of fuel. Landing speed 95 mph (light)-125 mph (loaded).

Weights

38,000 pounds empty, 56,000 pounds combat, 71,200 pounds maximum overload.

Dimensions

Wingspan 110 feet 0 inches, length 64 feet 2 inches, height 18 feet 0 inches, wing area 1048 square feet. Fuel: 2364 US gallons in main tanks, plus 450 gallons in auxiliary wing tanks and 800 gallons in extra tanks fitted in bomb bay if required.

Accommodation

Crew was normally ten (pilot, copilot, bombardier, nose gunner, navigator, radio operator, ball turret gunner, two waist gunners, and tail gunner). Armament: Ten 0.50-inch Browning machine guns in nose, upper ventral, and tail turrets and in waist positions. Maximum internal bomb load was 8000 pounds. Two 4000 pound bombs could be carried on external racks, one underneath each inner wing. Maximum short range bomb load was 12,800 pounds (by using under wing racks), but normal offensive load was 5000 pounds.

Sources

461st Bombardment Group: http://www.461st.org/Aircraft/Liberator.htm

Legends In Their Own Time: http://legendsintheirowntime.com/B24/B24_index.html

The Collings Foundation: http://www.collingsfoundation.org/menu.htm

i/ota Internet Services Panorama Technical Imaging: http://i-ota.net/B-24Witchcraft/

ibiblio Hyper War Website: http://www.ibiblio.org/hyperwar/USN/ref/AirGunnery/

Joe Baugher Website: http://www.joebaugher.com/usaf_bombers/b24